CNC Machining Service

CNC machining plays an important role in the manufacturing industry.

If you are in search of a one-stop solution provider for CNC machining components, BTN Industry should be your first choice. We have a network of professional CNC machining experts that aim to provide maximum precision in the CNC machine parts. BTN Industry has been offering world-class CNC machining services for more than a decade. Together with our modern machining equipment, our experienced team works day and night to deliver you the precision parts with utmost accuracy.

BTN Industry is a top-of-the-line CNC machining service provider in China, but we extend our premium services to customers around the globe. Our team is well-trained and highly qualified, to guarantee you the delivery of high-standard CNC machined parts with extreme precision. Despite the high efficiency and modern CNC machines, BTN Industry offers services at economical rates. Our top priority is to fulfill the requirements of our valuable customers through our high-quality and sustainable products.

3 Axis Machining

We have 20 sets of high-performance, high-precision vertical 3-axis CNC machining centers. Since only one side can be machined, but not the sides and other sides, the 3-axis machining center is capable of machining disc, sleeve and plate parts, etc.

4 Axis Machining

We have 12 sets of vertical 4-axis CNC machining centers. High precision, good stability, multi-face machining by rotation, improve machining efficiency, reduce the number of clamping, suitable for cylindrical parts, shell parts, disc-shaped parts, etc.

5 Axis Machining

We have 4 sets of high efficiency and high precision vertical 5-axis machining centers. It can machine complex-shaped parts to meet the requirements of the aerospace industry. It is also suitable for machining molds for the automotive industry.

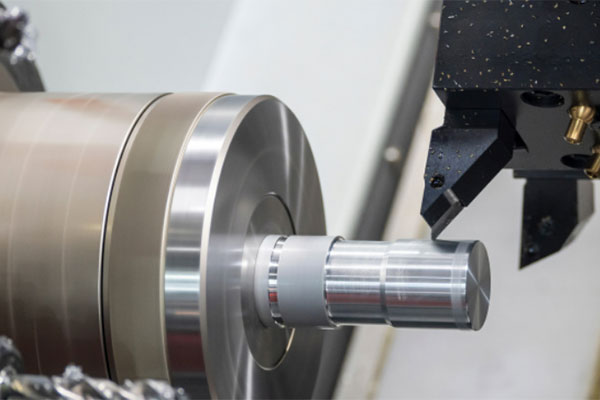

Cnc Turning Services

CNC turning service is the core of our high precision machining capability. Customized precision CNC turning service, providing high-quality CNC lathe parts. professional OEM/ODM CNC turning service. The products are roughly divided into sleeve parts, shaft parts, washers, bolts, etc.

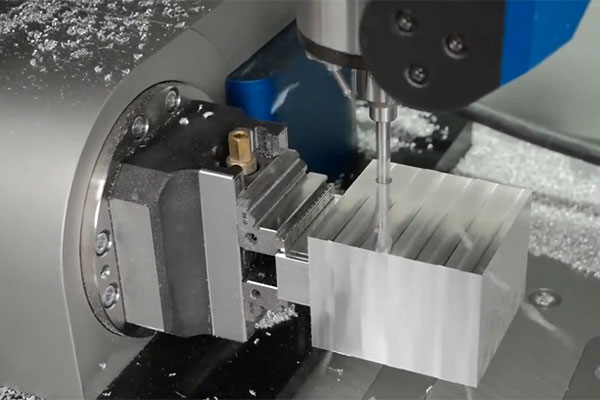

CNC Milling Service

CNC milling operations include end milling, end milling,face milling & drilling, boring, tapping, etc. It is a very universal fabrication method with great accuracy and tolerances. Milling is suitable for a variety of materials and is also very quick. The ability to manufacture a wide range of complex parts is a great advantage.

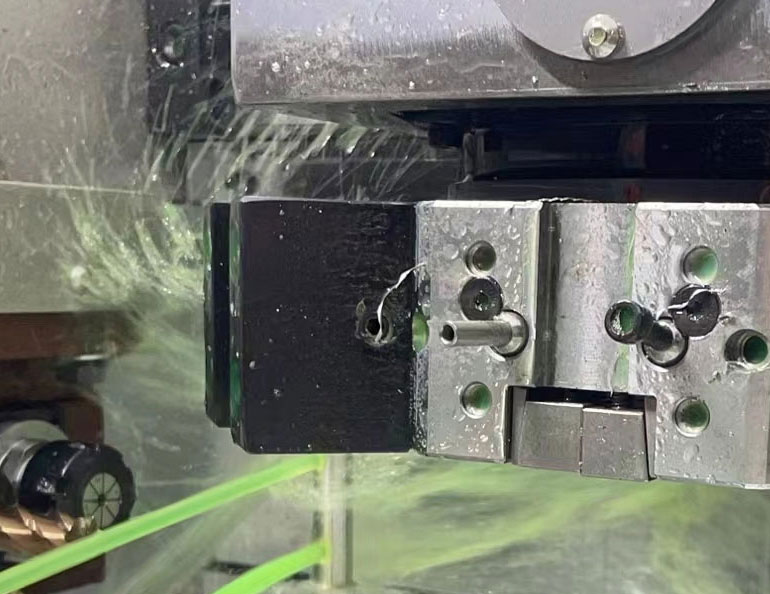

Wire EDM

EDM(Electrical Discharge Machining), also known as wire-cut EDM can be used in everything from prototypes to full production runs, and is most often used to manufacture metal components and tools. EDM drilling makes it possible to create very small holes, EDM is used often in the production of circuit boards.

CNC grinding

CNC grinding involves removing small amounts of materials via a high-speed abrasive wheel as the cutting tool. There are five types of CNC grinding,surface grinding,centerless grinding,cylindrical grinding, internal grinding& special grinding.

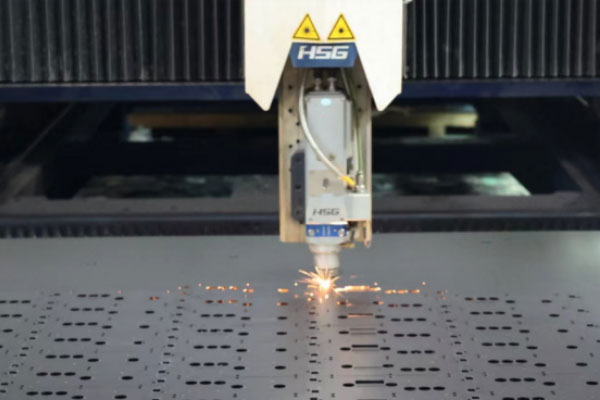

CNC Laser cutting

Laser cutters use a high-energy focused laser beam to cut materials with high speed and extreme accuracy. It can be used to create parts for medical devices, computers and electronics, and much more. Materials that are difficult or impossible to cut using other methods make excellent candidates for laser cutting.

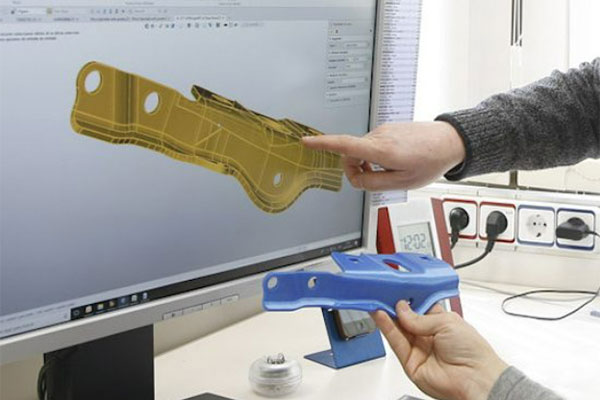

Rapid Prototyping Services

Rapid prototyping is the quickest way of bringing a preliminary version of an idea to life. Low volume and high efficient to help engineer to bring any customed new developed components into market.

Our Advantages Of CNC Machining

We are able to deliver precise and rapid results consistently as we continually invest in state-of-the-art CNC machinery, train our staff to the highest standards, and ensure that everything we manufacture exactly matches the customer specification.

01:Advanced Equipment

Using the latest CNC Machines, including 3-, 4-, and 5-axis CNC milling, produces highly accurate samples in as fast as 3-5 days.

02: Rich Experience

With a professional engineers team and over 15 years of industry experience, we can smoothly handle complex, precision parts for multiple industries.

03:Precision Tolerance

High precision tolerance ranging from +/-0.02mm, depending on the technical drawing.

04:Fast Turnaround

We send your quotes within 24 hours on average, samples are shipped within 3-5 days, and we have an on-time delivery rate of over 90%.

05: Well trained QC team

Prior to shipping, products will be double 100% full inspected and data recorded.

Applications Of CNC Machining

.Automotive (CNC machining can be used to create several important components of a car’s combustion engine, lights, suspension components, exhaust parts,etc and CNC machining is more cost-effective when dealing in larger volumes)

.Medical (CNC machining can create surgical instruments used by medical professionals during operations. These metal components may include surgical scissors, biopsy tubes, blade handles, cutters, saws, forceps, implant holders, clamps, spacers, plate benders, and more.)

.Electronics (Many electronic devices and their components are manufactured using CNC machining, such as keyboard,sockets, terminals, etc, BTN industry is a specialized precision machining supplier with the ability to manufacture complex and high-precision components for electronic components.)

.Communication facilities (BTN industry has extensive experience in machining parts for communications equipment, such as heat sinks,etc)

.Military industry (BTN industry offer gun parts to customers for 10 years, we have rich experience in machining it)

.Tools (Our CNC machining service help our clients produced many their designed tools.)